Bridgestone’s High Damping Rubber Bearing Analysis Model for Design of Seismically Isolated Structure Employed in ETABS and SAP2000 Structural Analysis Software

TOKYO (July 24, 2018) — Bridgestone Corporation announced today that it has developed an earthquake response analysis model for its high damping rubber bearings,*1 one of its seismic isolation rubber product lineups, with the cooperation of Adjunct Professor Kazuhiko Kasai of the Tokyo Institute of Technology and Professor Masaru Kikuchi of Hokkaido University. The analysis model has been employed as a menu option for the ETABS and SAP2000,*2 structural analysis software of the United States’ Computers and Structures, Inc., which are widely used for designing seismically isolated buildings, bridges, and other structures.

This analysis model, called deformation-history integral type model (DHI model), is able to reproduce, with a high degree of accuracy, the deformation characteristics*3 of high damping rubber bearings, which has previously been difficult to model. The adoption of this model in the widely used software will make it easier to perform analyses when constructing seismically isolated structures using the Company’s high damping rubber bearing while also allowing for more accurate designs to be made.

Bridgestone provides a wide range of seismic isolation rubber products to meet various customer needs. Its high damping rubber bearings have been installed in more than 700 buildings*4 including residential buildings, warehouse, hospitals and factories since the first installation in 1988. Bridgestone will continue to utilize its sophisticated polymer compounding technologies to create a robust lineup enabling it to propose products and services that meet customer needs. Our goal in this quest is to contribute to safety and security by supporting people and their lives from the ground-up.

*1. A laminated rubber structure that includes a special filler compound in the rubber itself to provide energy absorption performance.

*2. ETABS ver.17.0.0 or later and SAP2000 ver.19.2.0 or later

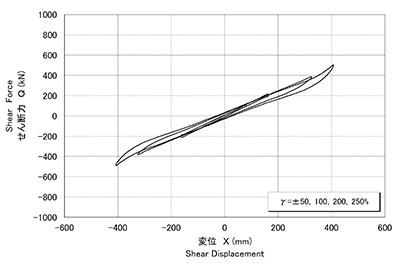

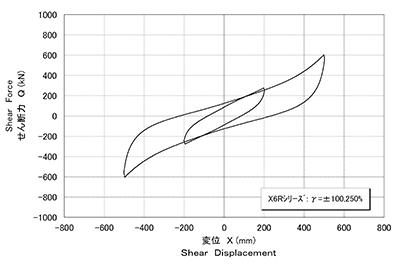

*3. Standard natural rubber bearings have a low capacity to absorb energy, making it difficult for shear force to change resulting in a shear stress-displacement curve that is essentially a straight line, as seen in Figure 1 below. High damping rubber bearings, meanwhile, have a high capacity to absorb energy. Accordingly, the seismic isolation rubber changes its shape in response to seismic vibrations, and, as the rubber returns to its original shape, it absorbs energy and shear force weakens. This results in a deformation graph that displays a square-shaped stress-displacement curve, as seen in Figure 2 below.

Figure 1

Figure 2

*4. As of December 2017

Related links: Bridgestone’s seismic isolation rubber product web page

About Bridgestone Corporation:

Bridgestone Corporation, headquartered in Tokyo, is the world’s largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.