PRESS RELEASE

Enhanced curb docking system

Tokyo (Jan 24, 2017) - Bridgestone Corporation (Bridgestone) announced a joint-research project with Yokohama National University (Professor Fumihiko Nakamura of the Transportation and Urban Engineering Lab) and the Japan Transportation Planning Association. The goal of the project is to enhance curb docking by enabling bus tires to more closely approach curbs in order to minimize the gaps between boarding entrances and bus stops. A concept for a next-generation curb docking system and road edge design was developed recently from research conducted with the project. Development is also underway for a tire technology that enhances the wear-resistance of the side of tires approaching the curb.

The project will continue to improve existing ideas for curbs and develop new concept tires that will make boarding easier for physically-challenged individuals. While incorporating input from both bus riders and drivers, Bridgestone aims to complete these technologies and find practical application for them by the year 2020.

The need for more accommodating and convenient public transportation systems is expected to rise in the future. For fixed route buses, rapid transit buses and other buses, removing obstacles to allow for easy boarding continues to be an important consideration. There is also a need to enhance curb docking for buses in order to minimize the gaps between bus entrances and stops to allow for peace of mind and smooth boarding for individuals who currently have difficulty using public transportation.

Joint Research on Curb Docking

Bridgestone began working with Yokohama National University in October of 2015. The Japan Transportation Planning Association joined the project in August of 2016. As part of the research project, Bridgestone is working to address the following needs:

- The ability to enable buses to smoothly and consistently approach curbs without placing additional burden on drivers. The research project aims to reduce disparities in the gap between tires and curbs, while also minimizing shock that occurs from contact with the curb.

- Minimize the damage to tires resulting from direct contact with curbs by evolving current methods such as to make tire sidewalls thicker

Solutions Utilizing Shapes of Curb and Road Edge

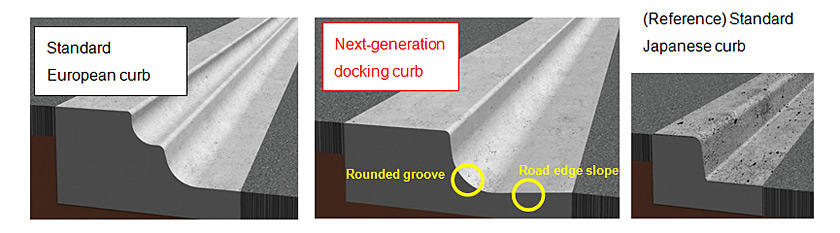

Bridgestone recently introduced the idea for a road edge slope that will enable buses to approach curbs naturally with minimal steering wheel manipulation. The road edge slope would serve as a means of controlling the angle of approach to the curb that is not dependent on the driver's skill level. In addition, Bridgestone formulated the concept of a next-generation docking curb together with a concrete shape proposal. This concept entails a rounded groove on the side of curbs to reduce the shock from tires making direct contact with the curb.

In formulating this concept, Bridgestone employed various sensors to measure vehicle behavior in order to determine the dominant factors affecting curb docking. In addition, Bridgestone developed a new means of simulating the approach of vehicles to bus stops to aid in discovering the ideal shapes of curbs and road edges.

Bridgestone installed next-generation docking curbs at the company's proving ground in Nasushiobara City, Tochigi Prefecture. Tests were conducted using actual buses to verify the effectiveness of the above-mentioned concept. The results of the testing showed that the next-generation docking curb was able to reduce the gap between the curb and the bus to half the gap that occurs with standard European curbs. The testing also was able to reach the target of less than 40 mm and succeeded in lowering the disparity in the size of the gap.

Solutions Utilizing Tires

From the perspective of bus tires, Bridgestone has been developing a wear-resistant technology for reducing the damage to tire sidewalls from contact with the curb. The wear-resistant technology is based on the concept of reducing the abrasive energy generated from contact between the tire and the curb. The benefits of this technology have been confirmed through tests of prototypes. Based on quantitative data on the damage from curb contact collected through tests and simulations, we anticipate that this material will help reduce wear to tire sidewalls by approximately 30 percent.

Bridgestone aims to contribute to the development of public transportation systems that present no barriers of usage for the physically challenged. Bridgestone continues to develop solutions that address the various needs of our customers through the development of technologies, products and services based on global input from our customers and employees.

Photographs of tests conducted at Bridgestone's proving grounds

About Bridgestone Corporation:

Bridgestone Corporation (BSJ), headquartered in Tokyo, is the world's largest tire and rubber company. In addition to tires for use in a wide variety of applications, it also manufactures a broad range of diversified products, which include industrial rubber and chemical products and sporting goods. Its products are sold in over 150 nations and territories around the world.